The Summer Sweet Spot: Scheduling Off-Season

When it comes to business aviation, timing is paramount. This is especially true for aircraft maintenance. For many operators maintenance events can often fall at the most inconvenient time. November through March, both flight activity and maintenance demand reach their peak, which often creates scheduling challenges for operators. While the surge in flight operations around this time is mainly due to year end board meetings and holiday travel, annual maintenance often coincides with this season for separate, scheduling-related reasons.

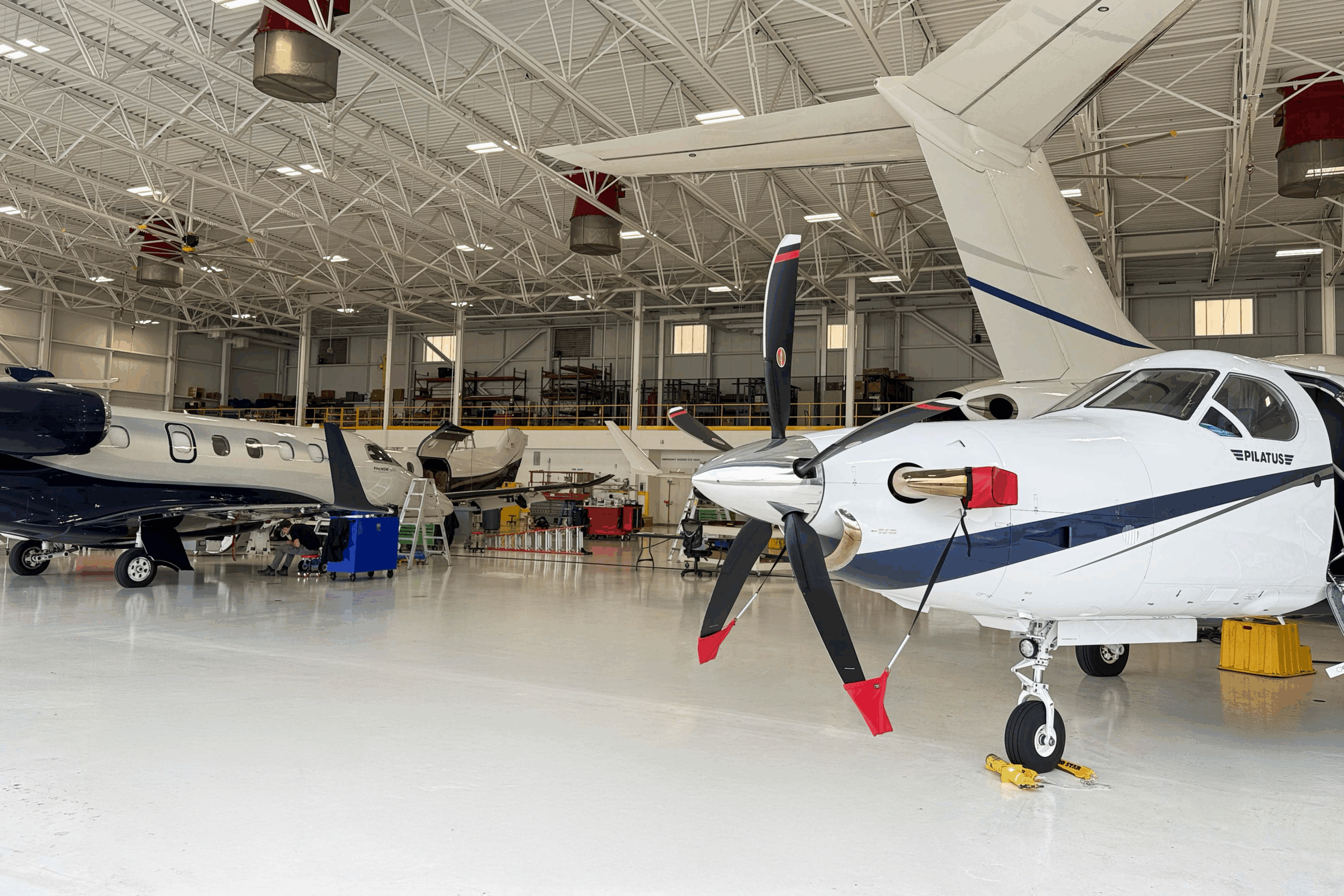

Pilatus and Embraer aircraft, like many others, are typically delivered in the latter half of the calendar year, particularly in Q4. The initial date that the aircraft is delivered and certified almost always determines when recurring inspections will be due. This creates a cycle that, unless intentionally broken by the aircraft owner, contributes to the congestion that service centers face during the winter months. This can create an unnecessary burden for aircraft operators. But, it does not have to be this way.

Proactively shifting business jet inspections to the summer months can actually offer several distinct advantages for aircraft owners. The most prominent benefit, of course, is slot availability. With less demand at service centers in June, July, and August, there will be much more flexibility for owners to choose downtime that specifically fits their needs. In addition to this, faster turn times can also be expected for summertime maintenance. Naturally, during slower periods, shops can dedicate more technicians to a single job, which often results in a reduced total downtime. On top of that, when maintenance teams are not stretched as thin, there is more focus placed on quality and efficiency.

The potential upsides of summer maintenance don’t end here, however. Winter months also introduce delays in parts logistics, especially during the holidays. In fact, many OEMs reduce staffing during Thanksgiving and Christmas, making it harder to get parts on time and technical support. In contrast, the summer generally sees faster delivery of parts and quicker response times from manufacturers. For this reason, summertime inspections often allow more direct interactions with the technicians, easier coordination of cosmetic work, and even opportunities to travel or enjoy nearby destinations while the aircraft is down. But, how exactly does shifting this schedule work? It is actually simpler than it may seem. Pilatus aircraft, for example, follow a rolling 12-month calendar based on the jet’s last inspection. This means that if the annual inspection is moved from December to August, the next inspection would be due the following August. This one adjustment can easily realign maintenance with quieter service periods moving forward. Similarly, with Embraer, the switch can be quite simple. Embraer aircraft do require a T-Zero reset to make this same shift. While this can occasionally be met with a fee, the long run benefits are likely to outweigh this. This process, however, formally resets the aircraft’s inspection timeline, essentially allowing aircraft owners to pick a brand new starting point for their annual inspections.

But, how exactly does shifting this schedule work? It is actually simpler than it may seem. Pilatus aircraft, for example, follow a rolling 12-month calendar based on the jet’s last inspection. This means that if the annual inspection is moved from December to August, the next inspection would be due the following August. This one adjustment can easily realign maintenance with quieter service periods moving forward. Similarly, with Embraer, the switch can be quite simple. Embraer aircraft do require a T-Zero reset to make this same shift. While this can occasionally be met with a fee, the long run benefits are likely to outweigh this. This process, however, formally resets the aircraft’s inspection timeline, essentially allowing aircraft owners to pick a brand new starting point for their annual inspections.

While some operators hesitate to move their inspection months earlier, there can actually be benefits to this too. When an aircraft is brought in months ahead of schedule, it is unlikely to accumulate enough hours to trigger significant maintenance tasks. This can actually result in an inspection that is much smoother and faster than a standard inspection. Simultaneously, this restarts the aircraft’s maintenance schedule, which will only continue to benefit the aircraft owner as time marches on. For operators seeking to reduce downtime, improve efficiency, and avoid winter delays, summer inspections may be the exact sweet spot they are looking for.